Super User

TNA feeding ambitions: Kingsway Confectionery increases capacity by 50%

Fast and flexible packaging solutions from TNA help to meet growing demand

Kingsway Confectionery, a renowned family-owned company specialising in packaging retail-ready products for over 30 years, has strengthened its position as a leading confectionery packaging company in Australia through its longstanding partnership with TNA solutions. In its latest facility upgrade, TNA's integrated packaging solution has enabled Kingsway Confectionery to increase production capacity by 50% and meet the demands of its expanding customer base. With state-of-the-art, Australian-made machinery, TNA offers fast changeovers, superior product flexibility, easy maintenance and cleaning, and optimised speed performance. Its unmatched customer support ensures high production uptime, keeping Kingsway Confectionery’s customers happy.

Supporting growth with speed and flexibility

To remain competitive in the confectionery market, Kingsway Confectionery recognised the need for machinery that could enhance performance and speed. Seeking a solution that could support a wide range of bag sizes, cater to its diverse customer base, and provide a strong return on investment, Kingsway Confectionery integrated a third tna robag® vertical form, fill and seal (VFFS) packaging system into its production line.

The robag® is renowned for its high performance, offering exceptional speed and flexibility. It empowered Kingsway Confectionery to efficiently package any type of snack or food application. Raymond Wicks, General Manager of Kingsway Confectionery, attested to the significant impact of the integration: "Adding a third robag machine increased our capacity by 50%. We went from 40 – 59 bpm to 80 – 100 bpm for bag sizes spanning anywhere from 30 to 400 grams."

In addition to improving speed and efficiency, the tna robag® seamlessly fit into operations as a complete solution. The integration with the tna intelli-weigh® alpha provided a simple and accurate weighing solution, enhancing flexibility for rapid product changeovers. This enabled Kingsway Confectionery to scale production capacity and meet the evolving needs of its customers without disruptions.

The tna robag® is the latest development in the evolution of VFFS packaging machines. With 99% output efficiency, tna robag enhances the production performance and efficiency.

The tna robag® is the latest development in the evolution of VFFS packaging machines. With 99% output efficiency, tna robag enhances the production performance and efficiency.

Keeping uptime high with timely maintenance

Beyond enhanced packaging capabilities, Kingsway Confectionery also highlighted the importance of timely technical support and readily available spare parts. TNA's global presence and commitment to customer support ensured that Kingsway Confectionery could resolve any challenges efficiently. TNA’s highly skilled technical support team, coupled with the availability of necessary parts, enabled Kingsway Confectionery to minimise downtime and maintain operational excellence.

Raymond expressed his satisfaction with TNA's support, stating, "Over the last 14 years, we wouldn't have had a machine down for longer than a day due to TNA's team helping us." The proximity of TNA's factory in Melbourne further facilitated swift access to spare parts, streamlining maintenance and support.

TNA continues to empower confectionery producers with innovative technologies and comprehensive support. The partnership with Kingsway Confectionery exemplifies the companies’ shared commitment to efficiency, quality and customer satisfaction.

To read the full case study on how TNA worked with Kingsway Confectionery, click here.

About TNA solutions

TNA solutions is a global leader in food processing and packaging solutions, committed to helping people succeed responsibly in a changing world. With over 40 years of experience, TNA’s global team of experts have installed more than 14,000 systems in over 120 countries. The company creates and sustains solutions that help customers realise goals and exceed their expectations, with performance, responsibility, and a customer-centric approach at the core of the business. A collaborative, consultative approach ensures measurable results and lasting success, with solutions designed to evolve and perform over time. As an inclusive partner, TNA supports a growth agenda that goes beyond business, emphasising its commitment to people, prosperity and the planet in harmony. TNA is a powerful advocate of social justice, and aims to support children in disadvantaged communities through education, healthcare, and social enterprise programmes, through the humanitarian initiatives undertaken by the Nadia and Alf Taylor Foundation.

TNA solutions: feeding ambitions

Visit www.tnasolutions.com

Wood signs global framework agreement with Shell

Wood, a global consulting and engineering company, has been awarded a multi-year enterprise framework agreement (EFA) to continue to provide services to Shell’s global projects.

Bringing specialist consulting, engineering, procurement and project management expertise to Shell’s greenfield and brownfield projects, the agreement will see Wood continue to support projects that ensure energy security and enable energy transition projects focused on carbon capture, low-carbon fuels and hydrogen. Wood will deploy expertise in decarbonisation, digitalisation and asset life extension to enhance Shell assets worldwide.

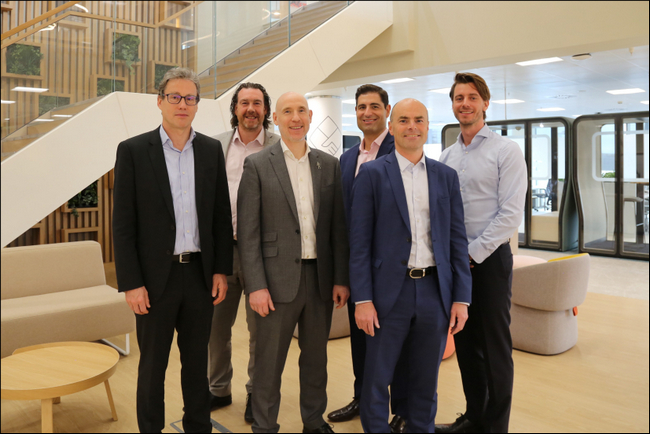

(L-R) Alistair Hope – Senior Vice President of Conventional Oil & Gas and Offshore Wind Projects, Shell; Paul Macgregor – EPC Management, Contracts & Procurement Manager, Shell; Craig Shanaghey – Executive President of Projects, Wood; Scott Commons – Vice President of Strategy & Development, Wood; Steve Nicol – Executive President of Operations, Wood; Chris Mijatovich – EPC Category Manager, Shell

(L-R) Alistair Hope – Senior Vice President of Conventional Oil & Gas and Offshore Wind Projects, Shell; Paul Macgregor – EPC Management, Contracts & Procurement Manager, Shell; Craig Shanaghey – Executive President of Projects, Wood; Scott Commons – Vice President of Strategy & Development, Wood; Steve Nicol – Executive President of Operations, Wood; Chris Mijatovich – EPC Category Manager, Shell

Under the three-year framework, with options for two one-year extensions, services will be provided by Wood’s consulting and engineering teams in Europe, North America, Latin America, South-East Asia, Australia and the Middle East.

Ken Gilmartin, Wood’s CEO, said: “This award continues a 70-year relationship between Shell and Wood, spanning more than 20 countries and numerous major projects. Complex project excellence is where we excel and we are aligned with Shell in our strategic ambitions to deliver the energy the world needs today while simultaneously delivering the energy transition at pace. We look forward to continuing to partner with Shell as we work to design a better energy future together.”

Wood is a global leader in consulting and engineering, delivering solutions to critical challenges in energy and materials markets. We provide consulting, projects and operations solutions in 60 countries, employing around 35,000 people. www.woodplc.com

Modular working in R&D labs

The automation of laboratories used to be considered very costly and not very flexible, because the workflows are very complex and amounts of data are constantly increasing. Yet, as chemical and pharmaceutical industry product lifecycles become shorter and shorter, the need for digitalization has become urgent. In this article, Christof Franzke, Senior Technical Consultant Key Accounts at COPA-DATA, the industrial software specialist, explains the vital role of the zenon platform in the roll-out of modularization and digitalization in laboratories.

Today’s consumers expect technologies to ‘plug and play’ and work seamlessly with other devices in the home — and the same qualities are required in industrial and manufacturing environments.

Digitalization has become somewhat easier over the years, thanks to the diversity of automated hardware now available. Yet, on the other hand, it is more difficult to achieve seamless and holistic connectivity across multi-vendor, multi-tenanted production sites. One way to achieve this is with an industry standard called Module Type Package (MTP).

Dubbed plug-and-produce manufacturing, MTP is an approach that enables all equipment in a central control system to communicate independently of the typically-fragmented hardware and software usually found in laboratories. Each individual work step is provided by a completed module and researchers in the lab can then combine these modules, quickly and repeatedly, into new applications and processes. What’s more, this can be achieved with just a few clicks and without the need for programming knowledge. Therefore, MTP helps to ease and democratise the whole process.

One company that has successfully implemented the MTP approach is Merck KGaA, a German multinational science and technology company. For the first time, Merck is applying its Industry 4.0, Smart Factory and the Industrial Internet of Things (IIoT) approaches, which are formerly tried-and-tested in production environments, to laboratories.

Modularised process development

Configuring a laboratory so hardware and software work in tandem is still a challenge to this day, as many labs still rely on closed, unconnected systems. To alleviate this challenge, Merck KGaA set out to make this automation as simple as connecting a printer to a PC.

When selecting system partners for its automation solutions, Merck KGaA attaches the greatest importance to open platforms and the independence of individual applications. For this reason, Merck KGaA and Siemens started a modularization project in 2021 for production facilities that manufacture innovative materials and products in the three business sectors healthcare, life science and electronics.

Independent of this, Merck KGaA has taken a further step with zenon from COPA-DATA. The software, which is designed to facilitate MTP standards and support modular production, was introduced to the research and development laboratories of the Electronics Technology Center at Merck’s global headquarters in Darmstadt, Germany

Merck KGaA and COPA-DATA’s systems enable the use of MTP standards in a higher-level Process Orchestration Layer (POL). This flexible application of modules is accelerating time to market considerably. The result is more efficient interaction between production and research and development (R&D) and accelerate the market launch of new products by up to 50 per cent.

Mass customization

Another growing demand in industry is customized products, and MTP can also support this goal. An important benefit of MTP modules is that data can be transferred seamlessly from the laboratory to production. This means formulas currently being developed in the laboratory can enter mass production immediately, without the need to waste effort on manually reconfiguring the production lines, thus enabling faster mass customization. Moreover, Merck KGaA expects that the boundaries between R&D and production will become increasingly blurred in the future.

Plug-and-produce is becoming an increasingly established method of production in today’s labs. With advanced industrial automation software like zenon, the chemical and pharmaceutical industry can be ready to cater for shorter product lifecycles, and a need for more customized products through the application of modular production.

To learn more about how zenon automation software from COPA-DATA can benefit modular production and mass customisation, visit its website.

About COPA-DATA

COPA-DATA is an independent software manufacturer that specializes in digitalization for the manufacturing industry and energy sector. Its zenon® software platform enables users worldwide to automate, manage, monitor, integrate and optimize machines, equipment, buildings and power grids. COPA-DATA combines decades of experience in automation with the potential of digital transformation. In this way, the company supports its customers to achieve their objectives more easily, faster and more efficiently. The family-owned business was founded by Thomas Punzenberger in 1987 in Salzburg, Austria. In 2022, with more than 350 employees worldwide, it generated revenue of EUR 69 million.

Evonik expands its rubber silanes production in China

Evonik, one of the world leaders in specialty chemicals, has expanded and started production at its rubber silanes plant, Evonik Lanxing (Rizhao) Chemical Industrial Co., Ltd. This state-of-the-art facility, a joint venture between Evonik Industries AG, DEG (Deutsche Investitions-und Entwicklungsgesellschaft mbH), and Rizhao Lanxing Chemical Industry Co., Ltd., is strategically located in the Rizhao Lanshan Chemical Industrial Park in Shandong province. The expanded plant is specifically designed to meet the growing demand for sustainable solutions within the global tire and rubber industry.

- Expanded facility greatly increases rubber silanes production capacity to meet growing demand for sustainable solutions

- Advanced technology implementation boosts efficiency, reduces waste, and lowers CO2 emissions

- Expansion reinforces Evonik's global rubber silanes production network and commitment to tire and rubber industries

The expansion of the regional product portfolio substantially increases capacity and provides a stable supply for customers with demand for liquid and solid rubber silane products. The regional production footprint was enlarged with grades previously produced only in Evonik’s European production sites. This capacity expansion further strengthens Evonik's production network for tire silanes, solidifying its commitment to supporting the evolving needs of its customers in the tire and rubber industries worldwide.

With a focus on sustainability and efficiency, the expanded plant has implemented advanced technology during the manufacturing process. The facility and technology is upgraded to reduce waste and side reactions while increasing product purity. Additionally, the plant will feature reduced carbon emissions, increased automation, and improved auxiliary facilities, including a wastewater pre-treatment plant.

“The expansion represents our continuous efforts to promote sustainability in China," says Fuliang Xia, president of Evonik Greater China. "We are able to better serve local customers from the tire industry with high-value, sustainable solutions. Furthermore, we are also contributing to the country’s green development agenda through reducing our footprint in production."

Head of business line Silanes, Peter Friesenhahn, further emphasizes the benefits of the expanded plant, stating, "The expanded production capacity, coupled with cutting-edge technology, ensures a stable and dependable product supply while facilitating our collaborative efforts with customers and partners to achieve sustainability goals in the silanes market.”

Alongside the existing sulfur-functional silane Si 69 and the solid silane admixture X 50-S produced on site, the product range will now also produce grades such as Si 75, Si 266 as well as the corresponding admixtures X 75-S and X 266-S. This expanded portfolio underscores Evonik’s commitment to sustainability while optimizing tire and rubber properties like low rolling resistance, high abrasion resistance, high mechanical properties such as tensile strength and low compression set.

Evonik continues to forge ahead in delivering sustainable solutions and remains dedicated to supporting the tire and rubber industries through innovation, expansion, and strategic partnerships.

Company information

Evonik is one of the world leaders in specialty chemicals. The company is active in more than 100 countries around the world and generated sales of €18.5 billion and an operating profit (adjusted EBITDA) of €2.49 billion in 2022. Evonik goes far beyond chemistry to create innovative, profitable, and sustainable solutions for customers. About 34,000 employees work together for a common purpose: We want to improve life today and tomorrow.

About Smart Materials

The Smart Materials division includes businesses with innovative materials that enable resource-saving solutions and replace conventional materials. They are the smart answer to the major challenges of our time: environment, energy efficiency, urbanization, mobility and health. The Smart Materials division generated sales of €4.83 billion in 2022 with about 7,900 employees.

Don’t forget commercial vehicles

Research by the RAC has revealed that the government is unlikely to meet its target of having six or more rapid or ultra-rapid electric vehicle chargers at every motorway service area in England by the end of 2023. So how does the land lie for the much larger, heavy-duty commercial vehicles that require infrastructure for high-power charging stations? Here, Roger Brereton, Head of Sales at steering system specialist at Pailton Engineering, discusses how to implement infrastructure more quickly.

~ It’s not only cars that require sufficient electrification infrastructure ~

ACEA, the European Automobile Manufacturers’ Association, estimates that trucks in the EU27 + UK region will need 10,000 – 15,000 higher power public and destination charging points by 2025, and 40,000 – 50,000 by 2030. By this latter date, ACEA also estimates that there should be 40,000 lower-power public overnight chargers at truck parking areas.

The need for these charging stations is reinforced by the fact that approximately 40,000 battery electric medium and heavy‐duty vehicles will be in operation in Europe in 2025. This figure is expected to rise to 270,000 by 2030.

Unfortunately, the infrastructure that is required to charge these larger electric vehicles is almost nonexistent today. This is despite a new law agreed by the European Union promising that 3,600 kW of truck charging capacity every 60 km will be installed along the EU’s primary motorways by 2030.

Unlike cars, commercial vehicles such as buses and trucks cannot use the existing infrastructure. Instead, dedicated high-power charging stations, commonly known as direct current (DC) fast chargers or superchargers, are needed to deliver high-voltage DC directly to the vehicle's battery.

Speeding up infrastructure implementation

As ACEA argues, the shortage of commercial vehicle infrastructure must be tackled urgently, with policymakers needing to take action to ensure a rapid infrastructure roll‐out.

The plan is to ensure adequate public charging by 2030. The Alternative Fuel Infrastructure Regulation (AFIR), a part of the EU’s “Fit for 55” regulatory action to make EU policies fit for reducing net greenhouse gas emissions by 55 per cent by 2030, states that there will be four charging stations in each designated safe and secure truck parking area.

Although it could be argued that the regulation has not gone far or fast enough, it must be acknowledged that it does provide manufacturers with a useful basis for their infrastructure roadmaps.

Bridging the gap

Due to the current rate of installation, heavy-duty original equipment manufacturers (OEMs) cannot wait for the charging challenge to solve itself. As result, companies should undertake a proactive study of their customers’ charging requirements, evaluate potential business models for strategic fit and then create an implementation roadmap for their chosen model.

Of course, customers will not obtain true peace of mind until charging anxieties are resolved. Fortunately, this risk can be somewhat accommodated for, by using route planning and battery monitoring services in the context of adequate charging infrastructure.

These monitoring services can provide real-time information about the availability and speed of charging stations along the planned route. This data can also be integrated into the route planning service, allowing drivers and fleet managers to make informed decisions about where to charge, helping to minimise wait times and optimise charging schedules.

With that said, the infrastructure that is required to charge these larger, heavy-duty electric vehicles is almost nonexistent, but there are policies in place to counteract this issue.

For charging stations in each designated safe and secure truck parking area to be installed by 2030, a rapid rollout needs to happen fast. Until now, it seems that the infrastructure for these larger vehicles has been somewhat ignored in the transition to e-mobility.

For more information about Pailton Engineering’s custom engineering for commercial vehicles, visit the www.pailton.com or call +44 (0)2476 680445.

About Pailton Engineering: Pailton Engineering Ltd design, test and deliver world class steering systems, using state of the art CAD (Solid Works), purpose designed and built test facilities, and state of the art manufacturing capability.

Hexagon equips the world’s first fully autonomous road trains

Hexagon AB, the global leader in digital reality solutions, combining sensor, software and autonomous technologies, has announced a landmark agreement with leading diversified mining company Mineral Resources (MinRes) to provide an autonomous haulage solution for a fleet of 120 fully autonomous road trains in Australia, which will transform safety, productivity and sustainability in the region.

The world-first, fully autonomous road trains are a full-site, truck-agnostic solution. The addition of unmanned and autonomous systems will form an essential part of the supply chain for the MinRes Onslow Iron project in Western Australia’s Pilbara region.

The centre of the autonomous platooning system is Hexagon’s autonomous solutions stack integrating drive-by-wire technology with an autonomous management system to orchestrate vehicle movement in road train haulage.

The centre of the autonomous platooning system is Hexagon’s autonomous solutions stack integrating drive-by-wire technology with an autonomous management system to orchestrate vehicle movement in road train haulage.

“At Hexagon, we see autonomy as a way to vastly improve our world,” said Paolo Guglielmini, President and CEO, Hexagon. “Today’s agreement with MinRes will ensure that off-road transport activities will be safer, more sustainable, and more productive. I’m excited to see how similar solutions can be applied in other off-road markets such as agriculture and heavy industry.”

“We’re excited to announce our agreement with Hexagon to deliver the world’s first fleet of autonomous road trains, which will be an essential part of Onslow Iron’s safe, efficient and dust-free solution for hauling ore,” said Mike Grey, Chief Executive, MinRes. “Automation will remove the risk of driver fatigue, lower operating costs and reduce fuel use and emissions. There’s enormous potential for these vehicles to transform mining across the world.”

Hexagon is the global leader in digital reality solutions, combining sensor, software and autonomous technologies. We are putting data to work to boost efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications.

Our technologies are shaping production and people related ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 24,000 employees in 50 countries and net sales of approximately 5.2bn EUR. Learn more at hexagon.com

About Mineral Resources

Mineral Resources Limited (ASX: MIN) is a Perth-based leading mining services provider, with a particular focus on the iron ore and hard-rock lithium sectors in Western Australia. Using technical know-how and an innovative approach to deliver exceptional outcomes, Mineral Resources has become one of the ASX’s best-performing contractors since listing in 2006.

BAM spin-off wants to speed up the welding process of wind towers eightfold

A spin-off of the Bundesanstalt für Materialforschung und -prüfung (BAM) has developed a groundbreaking approach that revolutionises the welding process in the manufacture of steel towers for wind turbines. The new technology could secure important competitive advantages for the German wind industry and could also be used in the construction of hydrogen pipelines or liquid gas tanks.

In a modern steel wind tower, the welds add up to a length of about 700 metres. Steel sheets up to 30 millimetres thick have to be joined together in several layers using the so-called submerged arc welding process. At present, this takes a total of almost 100 hours. This alone limits the capacity of the four remaining German production sites to about 520 steel towers per year - only about half of what the German government's expansion targets for onshore wind energy envisage. Further steel towers are bought from abroad, mainly from China, where they can be produced particularly cheaply due to low labour costs.

Significantly faster - and at the same time more cost-effective - the systems could be produced using the laser hybrid welding process. It requires only a single welding layer. But so far, this process has only been approved for sheets up to 12 millimetres thick in industrial use. The reason: when welding thicker sheets, drops form from the liquefied metal underneath the weld seam due to gravity. They endanger the stability of the later plant and would have to be reworked at great expense.

A team from BAM's Competence Centre Wind has now found a smart solution to this long-known problem: The scientists have developed a system of electromagnets that is attached to the welding zone. The magnets release a so-called Lorentz force that counteracts gravity. This prevents any drop formation at the weld seam. At the same time, the system works completely contactless. The innovation makes it possible to use the faster laser hybrid welding process without compromising safety, even for the thick steel sheets used in wind turbines.

With the help of electromagnets, the BAM start-up wants to reduce the welding time of a 120-metre wind tower from 96 to 12 hours. Cost savings of up to 90 per cent are possible as a result. Source: Gabriele Rohde/Adobe Stock

With the help of electromagnets, the BAM start-up wants to reduce the welding time of a 120-metre wind tower from 96 to 12 hours. Cost savings of up to 90 per cent are possible as a result. Source: Gabriele Rohde/Adobe Stock

Now the four scientists are setting up their own spin-off company. They want to develop their invention into a marketable system for industry in the next two years. They are supported by the EXIST funding programme of the Federal Ministry of Economics and Climate Action (BMWK). At the same time, they have access to the excellent research infrastructure of BAM, which has the most powerful high-power laser in Europe with 60 kilowatts.

According to Christian Brunner-Schwer, who is responsible for finance and sales in the team, the potential time and cost savings from the innovation would be enormous for a modern 120-metre wind tower: by using laser welding, which the magnet system makes possible, the welding time could be reduced from 96 to just under 12 hours - an acceleration by a factor of 8. At the same time, only 900 instead of 4000 kilowatt hours of energy would be needed. The costs for welding could be reduced by a total of 90 per cent. The CO2 emissions from the production of a wind tower would even be reduced by 93 per cent.

"Experts already confirm that our system could become a game changer for the wind industry," explains Fatma Akyel, who is responsible for research and development in the team. "At the same time, steel wind towers are only one field of application for our innovation. There is further potential wherever, thick-walled steel sheets are joined together: in the construction of hydrogen pipelines, of containers for liquid gas or chemicals, in ship and bridge construction."

Today's market analysis on behalf of Samer Hasn Market Analyst and part of the Research Team at XS.com

Gold continues to consolidate above levels of $1960 an ounce today, with anticipation of the Federal Open Market Committee (FOMC) interest rate decision.

The markets are almost completely expecting the decision today to be in favor of a 25-basis point hike. However, the focus of the markets will actually be on the tone of Jerome Powell's speech after the announcement of the decision. Where the markets are trying to strengthen their hypothesis that this expected hike today is the last in the path of monetary tightening followed by the Federal Reserve, which pushed interest rates to the highest levels in decades.

Today's Fed rate decision follows the many figures we saw earlier this month that indicated a continued slowdown in inflation. Annual inflation fell to 3% in June compared to 4% we had seen last May, the weakest reading since April of 2021. We had also seen annual core inflation, which excludes food and energy prices, decline to 4.8% in June. Compared to the 5.3% we had witnessed last May.

These figures, despite the significant decline recorded, are still higher than the Fed's targets at 2%. Accordingly, Powell may indicate in his speech today that keeping inflation away from the Fed's targets may necessitate maintaining monetary tightening and keeping interest rates at their current levels throughout this year. While the continuation of the hawkish speech from the Fed may keep pressure on gold prices and may prevent them from regaining their previous gains at levels above $2000 an ounce.

Also, gold may benefit from the expected pressure on the US dollar in the event that the European Central Bank maintains a very hawkish tone with its announcement of the interest rate decision tomorrow, Thursday, with the expectation that it will also raise by 25 basis points. We also await more data from the economy, both from the US GDP numbers for the second quarter, as well as the personal consumer expenditure price index (PCE) figures for June.

As for the US bond markets, we witnessed a decline in the yields of two-year Treasury bonds - which are highly sensitive to changes in short-term interest rates - to 4.839% during the peak of yesterday's declines, and down from 4.926% at the close of the previous session. While the declines in bond yields may reflect market expectations that monetary tightening will actually end, which may support gold prices.

NGK Receives Order for NAS Batteries Intended for Energy Storage Facility of SALA ENERGY

NGK INSULATORS, LTD. (hereinafter, “NGK”) has received an order for NAS® batteries for electrical power storage intended as those for an energy storage facility from SALA ENERGY CO., LTD. (hereinafter, “SALA ENERGY”), which is a subsidiary of SALA Corporation engaged in the energy business.

The NAS batteries have a capacity of 69,600 kWh (69.6 MWh) and can store electrical power equivalent to one day’s worth of electric power consumption by approximately 6,000 average households. The batteries will be directly connected to the electrical power grid at the SALA Hamamatsu Storage Station, which is located in Hamamatsu City. They are intended to stabilize the supply and demand of electrical power by storing electrical power when there is an excess supply and discharging it during shortages. As NAS batteries are featured with the large capacity and capable of continuous discharge for the long period, they can be used for multiple applications. SALA ENERGY plans to use energy stored in the batteries for trading in various electricity markets such as the supply and demand adjustment markets and capacity markets, as well as reducing the cost of procuring electrical power through arbitrage (*1) via the wholesale electrical power market. The NAS batteries are being introduced following SALA ENERGY’s selection as a business operator in the “Project to Support the Introduction of Storage Battery Systems and Water Electrolysis Equipment for Power Grids (Revised Budget FY2022)” (*2) led by the Sustainable open Innovation Initiative, which has been entrusted by the Agency for Natural Resources and Energy to implement the support business. It is expected that the NAS batteries will help to stabilize the supply and demand of electrical power, along with contributing to the expanded use of renewable energy, which can fluctuate significantly.

Although further introduction of renewable power generation, including solar and wind power, is anticipated as part of efforts to achieve carbon neutrality, the fact that the amount of power generated is affected by seasons and weather presents a challenge for renewable energy. Furthermore, managing the tightening supply and demand of electrical power due to factors such as climate change has become a social issue. Charging and discharging batteries for grid storage in line with supply and demand for electrical power can help to solve these issues.

NAS batteries are used in various applications including stabilization of renewable energy, electric power demand and supply balancing, and emergency power sources. They have so far been installed in over 250 locations worldwide and have a stable operational track record of more than 20 years. NGK will continue to meet the demand for large capacity storage batteries, such as those for grid storage, strive to promote the spread of renewable energy and stabilize the supply and demand for electrical power, while helping to realize a carbon-neutral society.

image of NAS batteries to be installed at energy storage station

image of NAS batteries to be installed at energy storage station

Overview of the Ordered NAS Battery

|

Installation site |

SALA Hamamatsu Storage Station (Hamamatsu City, Shizuoka Prefecture) |

|

Capacity |

69,600 kilowatt-hours (69.6 megawatt-hours) |

|

Units installed |

48 (container type) |

|

Applications |

Adjustment to supply and demand for electrical power, and provision of electrical power to capacity markets, supply and demand adjustment markets, wholesale markets and others |

|

Start of construction |

July 2023 |

|

Start of operation |

Spring 2026 (planned) |

About NAS batteries

NAS batteries are a megawatt class large-capacity storage battery, implemented practically for the first time in the world by NGK. The batteries feature large capacity, high energy density (compact), and long life, and can provide a stable supply of electric power with a high output over long periods of time. They have been installed at over 250 locations worldwide, with a total output of over 720,000 kW (720 MW) and total capacity of approx. 5.0 million kWh (5,000 MWh) installed. They are used for various applications, including peak cutting through load balancing and emergency power supply, as well as stabilization of renewable energy and construction of smart grids, thereby contributing to reduced environmental load and realization of carbon neutrality. NAS batteries have obtained the certification based on stationary storage battery safety standard UL 1973 (cell and module level) and a test report based on UL 9540A standard (*3), which is to verify batteries and storage battery systems fire risk, for confirming compliance with its evaluation criteria (cell, module and installation level) through the evaluation program of UL Solutions, a global independent safety science company. https://www.ngk-insulators.com/en/product/nas-about.html

(*1) Arbitrage:

Trading activity in which electricity is stored in the batteries when wholesale electrical power market prices are low and discharged when prices are high. This trading activity seeks to reduce the cost of procuring electrical power.

(*2) Project to Support the Introduction of Storage Battery Systems and Water Electrolysis Equipment for Power Grids (Revised Budget FY2022):

A project that subsidizes a portion of the costs for business operators who introduce storage batteries or water electrolysis equipment resources for power grids that enable the absorption of excess renewable energy and provision of alignment capabilities through such means as trading in various electrical power markets, with the goal of increasing the use of and expanding the introduction of renewable energy in order to achieve the energy mix of 2030 and carbon neutrality in 2050.

(*3) NAS batteries container type (including the single batteries and modules on mounted) are covered.

NAS and the NAS logo are trademarks of NGK INSULATORS, LTD., registered in the U.S. and other countries.

Valmet to deliver Valmet DNA Integrated Operations to Rohe Solutions Oy in Hamina, Finland

Valmet will deliver Valmet DNA Integrated Operations (IOP) for off-grid distribution management to Rohe Solutions Oy in Hamina, Finland.

The order was included in Valmet’s orders received of the first quarter of 2023. The value of the order will not be disclosed.

Rohe Solutions started a pilot with Valmet DNA Integrated Operations in October 2022 and were happy with the set-up and integration of IOP and the on-site gateway. They were also pleased with the strong safety features and the integration to Rohe’s internal Microsoft environment, enabling a safe and easy implementation.

Rohe Solutions started a pilot with Valmet DNA Integrated Operations in October 2022 and were happy with the set-up and integration of IOP and the on-site gateway. They were also pleased with the strong safety features and the integration to Rohe’s internal Microsoft environment, enabling a safe and easy implementation.

The platform is also suitable for biomethane container and hydrogen-based gases like synthetic methane, distribution, which makes it futureproof for the customer.

“Valmet DNA Integrated Operations can be taken into use easily and is a scalable solution for managing off-grid distribution of energy. It is an excellent fit for Rohe’s fast-paced operations,” says Tiina Stenvik, Director, Performance Solutions, Automation Systems, Valmet.

“We are aiming to provide the best customer experience and the Valmet solution is one piece to the puzzle to fulfill this target,” says Jani Hautaluoma, Head of Technology, Rohe Solutions.

Technical information about the delivery

The delivery will include the Valmet DNA Integrated Operations platform with the latest capabilities. The platform will measure levels and pressures of the gases transported as well as the plant operability in an Azure environment.

About the customer Rohe Solutions Oy

Rohe Solutions Oy is a joint venture of Hamina Energy and Alexela Energia. The company is engaged in the sales of natural gas and liquefied natural gas (LNG). Rohe provides LNG services based on the needs of industrial manufacture, heavy goods transport, and sea transport. The services range from the mere delivery of LNG to complete turnkey solutions.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com